Winter in Australia isn’t just chilly mornings and early sunsets—it’s also one of the most demanding seasons for truck drivers. Slippery roads, heavy rain, early-morning fog, and sudden changes in temperature all contribute to a higher risk behind the wheel. And if you’re heading into June with a chipped windscreen, you’re rolling the dice.

A compromised heavy vehicle windscreen doesn’t just affect visibility; it undermines the structural integrity of your cab. It can also put you in the crosshairs of compliance officers doing seasonal checks.

In other words, winter is not the time to ignore that crack.

How windscreen damage can snowball in cold weather

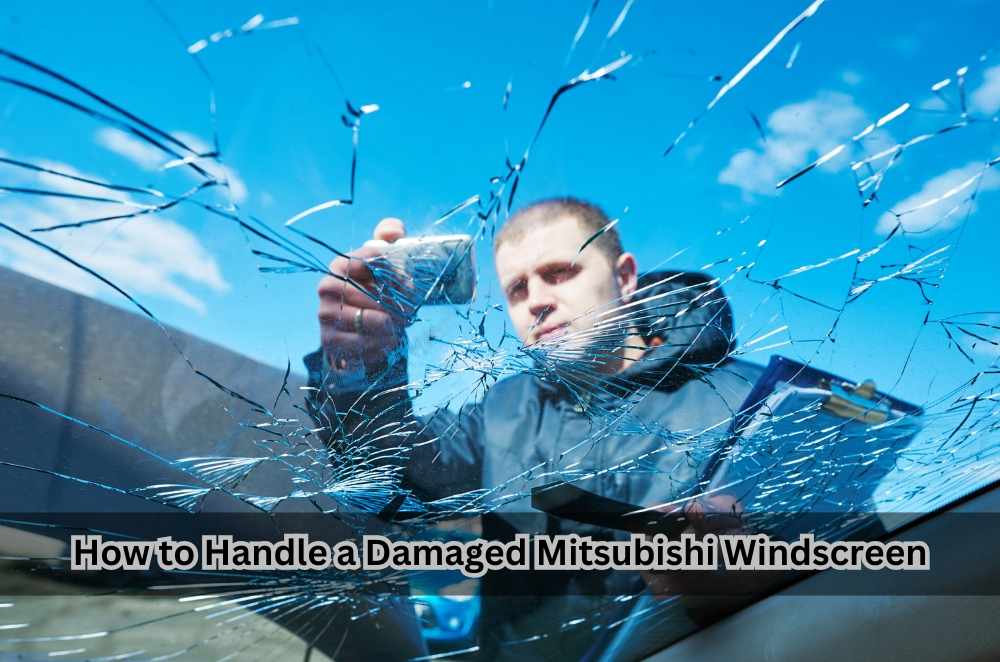

Let’s get real—chips and cracks are common, especially if you’re regularly driving regional or interstate routes. But cold weather changes how those cracks behave. When glass is exposed to low temperatures, it contracts. If you switch on your heater or demister quickly, that rapid change in temperature causes expansion… and that's when a tiny chip can turn into a full-blown crack in seconds.

I had it happen on the Hume. Started the morning with a 10mm chip from a stone flicked up by a livestock truck. It didn’t seem urgent. But by the time I reached Albury, it had spidered halfway across the passenger side—no pothole, no bump—just the heater doing its job too well.

Why truck windscreens are subject to stricter scrutiny

You’re not just driving a car with a big tray on the back. Trucks fall under heavy vehicle laws, which means more frequent inspections, tighter defect guidelines, and stricter roadworthiness standards. That includes the windscreen.

According to Australian guidelines on vehicle windscreen safety, any damage larger than 75mm (about the size of a credit card) in the driver’s field of view can result in a defect notice. It doesn’t matter if you think it’s still drivable. If it’s affecting your view or fails the visual zone checks, it’s a non-compliant vehicle.

Add to that the fact that many states conduct winter-specific roadside blitzes to check compliance on freight and logistics vehicles, and it’s clear why a clean, intact windscreen isn’t just cosmetic.

What counts as repairable

Here’s the thing: not every chip means you need a full replacement. But knowing when to repair and when to replace can save you both money and downtime.

Windscreen repair is generally suitable if:

The crack is smaller than a $2 coin

It hasn’t splintered or radiated outward

It’s not in the driver’s central vision

There’s no moisture or debris inside the crack

Replacement becomes necessary if:

The damage is longer than 7.5cm

Cracks are spreading under pressure

There are multiple chips, even if small

The damage is near the edge of the glass

One of our subcontractors had a windscreen replaced last July while running Brisbane-Adelaide freight. His windscreen had three small bullseye chips—none in the driver’s line of sight, but all within 10cm of the edge. The repairer flagged them as structural risks. Sure enough, within two weeks, one of the chips cracked right through in frosty overnight temps. Lesson learned.

Cost, downtime, and what your insurance may cover

Windscreen costs vary depending on your make, model, and whether you’re running a custom or ADAS-integrated screen. For standard trucks, you’re looking at $300–$600 on average for a full windscreen replacement in metro areas.

Time off the road? Less than two hours if you go with a mobile service.

Here’s the good news: many comprehensive insurance policies in Australia now cover windscreen repairs or replacements with no excess. But not all policies are created equal.

If you’re unclear on how insurance handles windscreen repair, including excess rules and common exclusions, it’s worth knowing where your policy stands before you need it.

Why ignoring the problem isn’t worth it

Some drivers delay repairs because “it’s only a small chip,” or they’re too busy during the freight rush. But here's why that approach can backfire fast:

Compliance penalties: You could be taken off the road mid-shift

Insurance issues: Delaying repairs may void your claim

Road safety risks: Cracked windscreens can shatter in a crash

Rain and water damage: Moisture seeps in, fogs up the inside, and can cause electrical damage

I spoke with a fleet operator in Geelong who shared a chilling story: one of his drivers ignored a top-corner crack. During a stormy run, the damaged seal failed, and water got into the fuse panel under the dash. The truck was out of action for a week, and it cost nearly $2,000 in electrical work, just because the windscreen wasn’t sorted early.

Quick tips for maintaining your windscreen in winter

Prevention is the cheapest strategy. These are the tips we give our own team before the colder months kick in:

Need a more thorough winter care routine? This seasonal guide to truck glass maintenance tips covers everything from anti-fog products to DIY inspections.

The wrap-up: Don’t let a cracked screen cost you

When you’re managing long routes, heavy loads, and tight delivery windows, the last thing you want is a compliance issue or safety risk due to a dodgy windscreen. Winter magnifies small problems, and windscreen damage is one of the easiest ones to get on top of before it spirals.

Whether you're driving a refrigerated B-double through Victoria or hauling timber up through Toowoomba, your windscreen is your first line of defence against the elements. That includes staying across what matters most in truck windscreens, from materials and maintenance to common failure points.

Make sure it’s doing its job.

Write a comment ...