A cracked windscreen never seems to happen at a convenient time. It can start with a small chip from a passing truck or a sudden line across the glass after a frosty morning. Either way, the decision to fix it usually comes down to safety and practicality. Driving to a workshop with limited visibility isn’t always the safest option, and finding a spare half-day to wait around is even harder. That’s why many drivers now choose mobile windscreen replacement as a more flexible solution. Instead of trying to shuffle life around a repair, the service meets you where you are—whether at home, work, or even a roadside site. It keeps you off unsafe roads, saves unnecessary travel, and delivers the same standards you’d expect in a workshop environment. For most people, that balance of safety and convenience is what tips the scales.

Why mobile fitment keeps your day moving

Mobile doesn’t mean “makeshift.” The same checks apply—just at your place. A good installer protects paintwork, keeps the cabin clean, and manages cure conditions so the glass actually does its job. If your car carries sensors behind the mirror, the visit can also include the calibration that keeps steering nudges and braking assists working as intended. The biggest win is time: you set the window, they set the screen.

Protect the bodywork and dash with covers before any trim comes off

Confirm the correct glass spec (HUD, acoustic layer, rain/light mounts) by VIN

Use primers and urethane within batch and temperature ranges for proper bonding

Check mouldings and clips; replace anything brittle rather than forcing re-use

Large operators such as O’Brien have built a reputation on demonstrating how consistent and safe mobile services can be. Their vans are equipped with the same calibrated tools found in a workshop, proving mobile fitment isn’t about compromise but about convenience. Out on site, environment matters. Ask for a flat spot with airflow under control; wind, dust, and steep driveways complicate things. A simple plan—clear bonnet access, space for doors to open fully, and nearby power if needed—keeps the visit efficient and tidy.

What actually happens during a driveway replacement

The sequence mirrors a workshop fit. First comes inspection and protection. Wipers and cowling off, trims eased back, then the old urethane is cut and the damaged glass lifted with suction handles. The aperture is cleaned, any bare metal is primed, and a fresh bead is laid to the height and profile the vehicle calls for. The installer sets the new screen onto locating blocks, checks depth, and refits the hardware. A water test follows, then guidance on when to drive and how to treat the car during early cure.

Confirm sensor brackets line up; a skewed mount throws cameras off by degrees

Record adhesive batch numbers; traceability supports workmanship warranties

Run a wind-noise check; mis-seated mouldings whistle before they leak

Provide care notes: door handling, tape timing, and wash avoidance during cure

Real-world note: I’ve had a small star crack turn into a line overnight after a cold snap. A mobile fit in a quiet car park sorted it without scrambling the week. No drama, just a calm install with the right tools.

Safety tech and calibration basics

Modern windscreens aren’t just transparent panels; they’re part of the structure and the sensor suite. Lane centring, traffic sign detection, and forward braking rely on clear optics and precise angles. After the screen goes in, a calibration step brings those systems back into alignment so steering nudges feel steady and alerts arrive when they should. Treat it as essential, not optional, if cameras sit behind the glass.

Use target boards or an approved dynamic route per the maker’s procedure

Verify camera yaw/pitch within tolerance rather than trusting a dash icon

Keep the inner glass spotless around sensors to avoid glare and false triggers

Document the calibration result alongside the fitment record

Motoring bodies like RACQ often highlight how critical this step is, reminding drivers that even a slight misalignment can affect safety. Alongside that, it helps to think of the windscreen as part of your vehicle’s protection package—just like seatbelts or airbags. Many car safety features rely on clear visibility and strong structural bonding to function as intended. If the glass isn’t fitted correctly, those systems can be compromised without you even realising it. A proper fit and calibration restore that safety net, keeping the technology working as it should whenever you’re on the move.

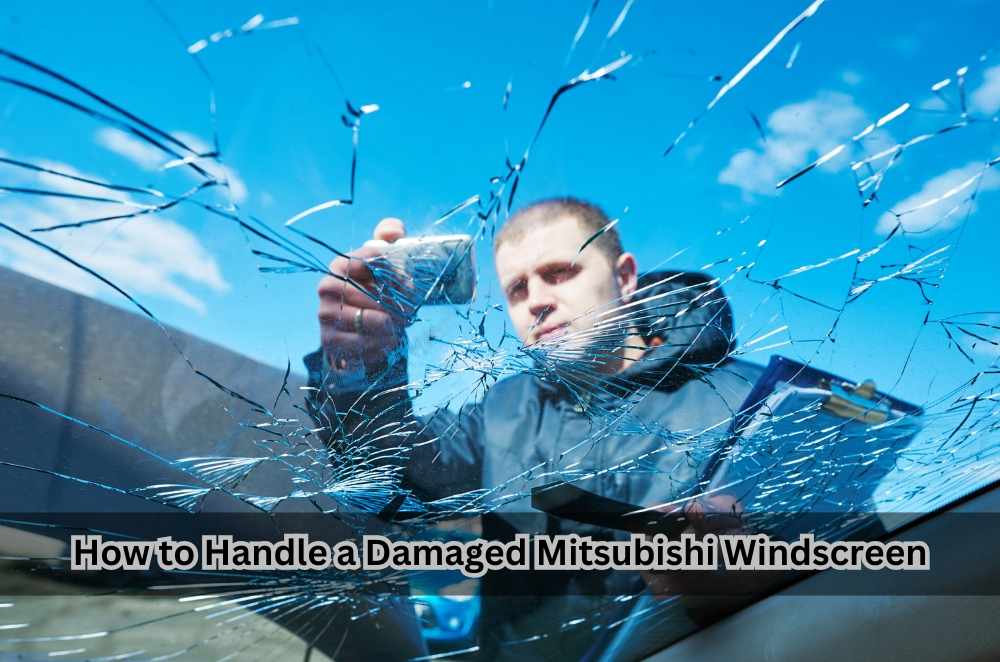

Repair or replace: choosing the right path

Not every mark needs a full swap. Small, clean chips away from the driver’s direct view can often be stabilised; structural cracks and edge damage call for a new screen. Use the damage location, size, and contamination as your decision inputs. If a mark has collected dirt or moisture in the laminate, repair results drop sharply. If a line runs from the edge, treat it as structural and act sooner rather than later.

Prioritise anything in the driver’s primary vision area for replacement

Treat edge cracks as structural; movement at the A-pillars flexes the glass

Look for haze or moisture between layers; that’s a sign to stop driving

Move quickly on fresh chips; clean damage stabilises more reliably

Drivers often wonder when to replace a windscreen instead of repairing it, and the answer usually comes back to safety. If visibility or structural integrity is compromised, replacement is the safer option every time.

Aftercare that prevents repeat damage

The first two days set the tone for quiet, dry motoring. Pressure spikes inside the cabin can disturb a fresh bond, and careless washing can nudge mouldings before they bed in. Keep things gentle, give the adhesive the environment it needs, and watch for small signs that trim hasn’t seated perfectly. If wind hum appears at one speed, flag it; small adjustments early avoid long-term noise.

Close doors softly and avoid slamming while the adhesive cures

Leave stabilising tape in place for the timeframe your installer specifies

Hold off on high-pressure washing and automated rollers during early cure

Listen for whistling at highway speeds; address it before it beds in

Of course, even with a fresh screen, stone strikes can still happen on highways or gravel roads. A tiny chip can sometimes be stabilised with resin before it spreads, but there are clear limits to what can be achieved. Understanding how to fix a windscreen crack gives drivers a realistic idea of what’s possible with a repair and when replacement is the only safe option. By acting quickly and knowing those limits, you can extend the life of your windscreen and avoid small damage turning into a bigger problem.

Final thoughts

Stay practical. Book the visit where the car actually lives during the day, clear a flat spot, and line up calibration if your mirror hides a camera. Keep doors gentle during early cure and pay attention to the first highway run; a quiet cabin is the sign the screen is seated right. When the next chip arrives—as they do—lean on a simple decision path: protect visibility and structure first, convenience second. That way, the glass keeps doing its quiet work while you get on with the week.

Write a comment ...